SuperFabric® materials share a common performance pedigree and provide durability, abrasion resistance, breathability and stain resistance in unique patterns and design. Since each material brings an exacting design and functionality, each SuperFabric® material will have varying levels of performance compared with other SuperFabric® materials. For example, stain resistance can depend on the particular pattern for that item number. Our knowlegable sales staff is ready to answer your questions. CONTACT them today for more information.

SuperFabric® brand materials are a foundation for products that last. SuperFabric® often extends the life of products when incorporated into high-wear areas. SuperFabric® materials are often praised for their toughness in grueling environment and conditions.

Depending on the application, a key component in durability is its ability to hold up against abrasion. There are many kinds of abrasions to keep in mind, such as rub wear tests, grinding tests, etc. Some materials perform better depending on the test being done. With that in mind, the chart below gives a general indicator on the abrasion resistance of various SuperFabric® brand materials. Also, note that this simply compares against other SuperFabric® materials. A low result, for example, may still be superior to other fabrics such as cotton, etc.

MODERATE

GOOD

700108-962

Here is an example of the use of SuperFabric® in the pouch of a tool-belt to help prevent abrasion damage

SuperFabric® brand materials provide a challenging barrier against a variety of razor-like threats. Small, durable guard plates precisely placed protect the underlying fabric from being torn or sliced. Unlike some cottons, knits, nylons, and other materials, SuperFabric® brand materials resist fraying. They also provide a high degree of resistance to scuffs that compromise protection and aesthetics, making them an ideal slash resistant material.

Here is an example of SuperFabric® being used in a glove to handle glass.

Our SuperFabric® materials have multiple amazing advantages that separate us from others in our industry, one of them being that our fabric construction is highly resistant to stains. The guard plates are very difficult to stain and small gaps between them (that allow our material to be flexible and breathable) are hard to penetrate. In short, the construction of this material alone is enough to surpass other fabrics. But we take it a step further, extending the stain resistance by treating the base fabric with quality water repellent. When all the components come together it results in a material that is very easy to clean and is highly stain resistant.

Some examples of how stain resistance SuperFabric® is

Hard to stain, easy to clean makes SuperFabric® materials an easy choice in tough environments.

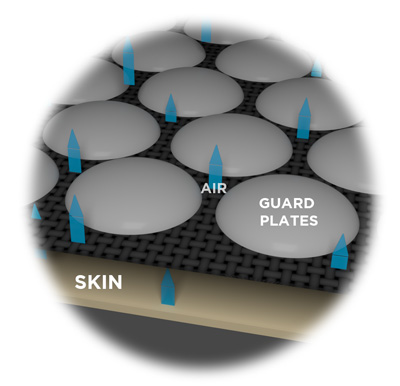

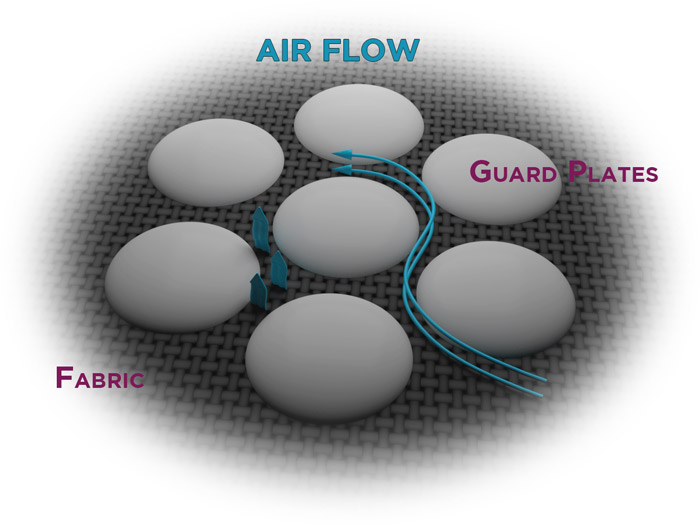

Many fabrics tout their ability to be waterproof but fail to mention that they restrict air-flow. In order to have footwear, jackets, pants, etc. be comfortable in a range of conditions, you need the material to be both water repellent and breathable. A true waterproof material such as rubber certainly keeps the rain and moisture out, but quickly traps moisture/sweat in, resulting in a 'wet/damp' feel and creating a highly uncomfortable situation. SuperFabric® provides a highly balanced solution of water resistance (outside) and air breathability (inside). The small gap between guard-plates allows flow of air around and through.

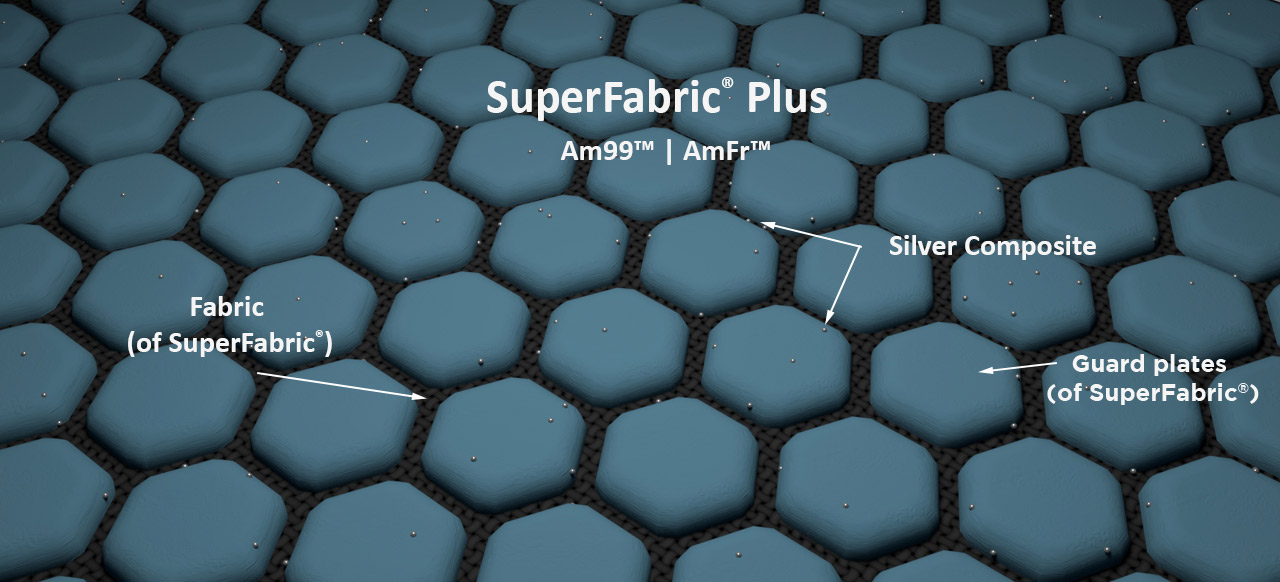

SuperFabric in the Am99™ or AmFr™ family of products is a highly effective antimicrobial fabric. The antimicrobial efficiency remains the same even after many cycles of washing and drying. Antimicrobial efficiency was tested and certified by the world-renown laboratories of TUV-SUD in 2016 and 2019.

RESISTS:

VIRUSES | BACTERIA | FUNGI | MOLD | MILDEW | ALGAE

First, it does not use nanoparticles as does conventional antimicrobial fabrics. It is silver ions (ionized silver atoms) in water. Conventional antimicrobial fabrics (CA-fabrics) use silver nanoparticles as an antimicrobial agent. Silver has very low water-solubility and therefore hardly dissolves in water. This means SuperFabric® antimicrobial fabrics use MUCH LESS SILVER than CA-fabrics. SuperFabric® antimicrobial fabrics do this by encapsulating the antimicrobial agent into the guard plates:

▶ It uses LESS silver

▶ It does NOT wash away

▶ It delivers antimicrobial agent in a much MORE effective way

▶ It uses NO silver or copper nanoparticles

▶ RETAINS other SuperFabric® properties such as stain and abrasion resistance

YONSEI HOSPITAL in Seoul, Korea

Here is a waiting area at the hospital with chairs that have been covered with SuperFabric®-AmTex™ material. Clean, durable, stain resistant SuperFabric® looks amazing. Yonsei is one of the largest hospitals in the world and sees over 3 million outpatients and more than 1 million inpatients each year. It is a world renowned and highly respected health care facility.

MORE CHAIRS...

With such great results of the chairs, Yonsei will continue to replace more chairs in waiting rooms. We can't wait to see other applications at Yonsei.

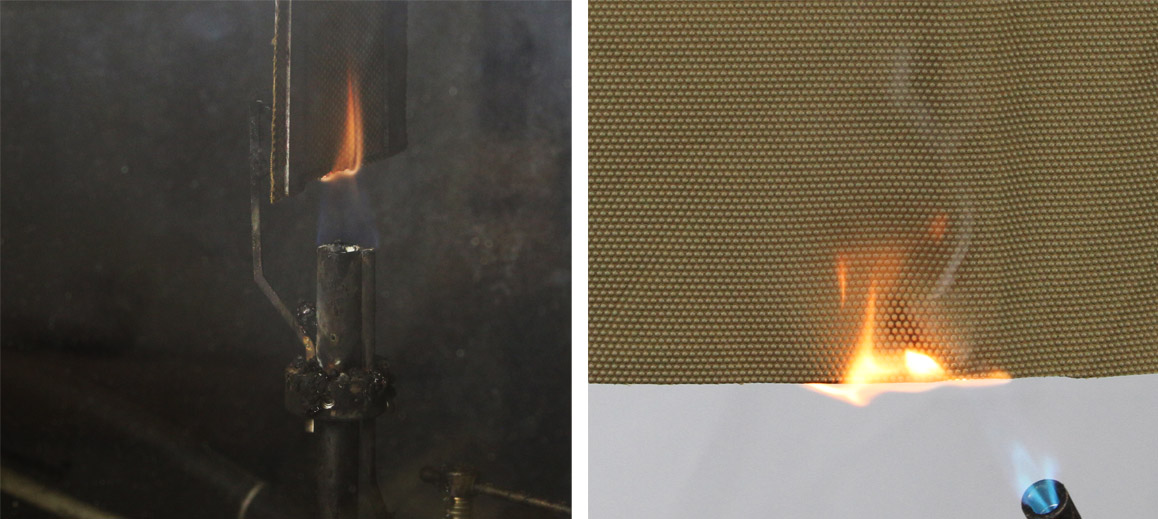

A new line of SuperFabric® materials that is both antimicrobial AND fire/flame resistant. It has the same antimicrobial capability as Am99™ line but now with added flame/fire resistance.

On the left, an AmFr™ sample (701505-065) passes an industry standard Vertical Flame Test. On the right, additional, more intensive test reveals the effectivness of AmFr™.

The AmFr™ line has many potential applications that need both fire/flame resistant materials and microbial resistance on top of the usual SuperFabric® properties such as durability, stain resistance, slash resistance, quick drying, etc. This includes markets such as mass transit (airplane, bus, and train seating), military, covers and more.

Check out the latest literature for additional information. Contact your SuperFabric sales rep for more information.

SuperFabric® drying is the result of a multifaceted structure that quickly dries, while keeping the elements on the outside. When liquid comes in contact with SuperFabric®, the molecules bead up on the surface, instead of being absorbed into the materials. Impervious guard plates, repellent fabric, and optional waterproof breathable membranes are all components of the advanced Speed Dry capabilities found in all SuperFabric® materials.

SuperFabric® materials simply don’t retain liquid because of the guard plates and breathable design. When testing SuperFabric® materials, we have found that they are able to dry more than 10 times quicker than untreated leather. Dry material means less weight. Dry material means more comfort and the ability to last longer and even in more extreme conditions. Materials such as leather that are constantly exposed to water can rot, deteriorate, and crack, therefore shortening product life and performance.

SuperFabric® materials are designed to the elements, resulting in superior performance and products. Unlike many other materials, SuperFabric® materials are not surface treated; the waterproof, breathable and quick drying fabric design is a result of the complex and innovative construction of our custom created specialty fabrics. Surface treated materials will lose their performance over time as the treatment wears off through use, washing, etc. but the performance of SuperFabric® materials will last long after our chemically sprayed competitor's materials wear out.